Data logging at Forsmark nuclear power plant

A high-channel distributed and synchronized data acquisition system

“Lundby is a standard system that not only fulfills our high demands, but also provided by a reliable supplier that will secure long term development and maintenance.”

– Magnus Hillerdal, Technical Lead at Forsmark Kraftgrupp

The story of Forsmark

Forsmark is the youngest of Sweden’s nuclear power plants and was commissioned in the 1980s. Forsmark has three boiling water reactors that generate 20-25 billion kilowatt-hours of electricity in a normal year. This is approximately one sixth of Sweden’s total electrical energy consumption.

Currently Forsmark is investing for the future with the purpose of extending the lifespan of the facility as well as increasing its capacity.

Figure 1. Forsmark reactor 1 and 2

The Challenge

Replacing the old logging system at Forsmark with a next-generation solution capable of meeting the high demands essential for a nuclear power plant.

The Solution

A distributed and synchronized data logging system with a high sampling rate and advanced triggering functionality.

Combining the benefits of NI CompactRIO and CompactDAQ data acquisition devices with WireFlow’s system architecture and software for distributed and synchronized data logging has provided Forsmark with an ideal solution poised to serve them for years to come.

The story of WireFlow’s Lundby Data Logger

WireFlow was founded in 2011 with the ambition to develop state-of-the-art test and measurement systems. Today, the company has grown to become one of the leading in Europe within its niche. WireFlow offers both standardized off-the-shelf products and customized solutions within the field of test and measurement. One specific area of WireFlow expertise is the development of large data logging systems. The Lundby data logger is WireFlow’s standardized data logger system, based upon hardware from National Instruments (NI). Utilizing the NI world-class hardware platform, the Lundby data logger can offer a vast array of different types of acquisition modules. The Lundby logger system supports all NI hardware platforms, such as CompactRIO, CompactDAQ, PXI and FieldDAQ.

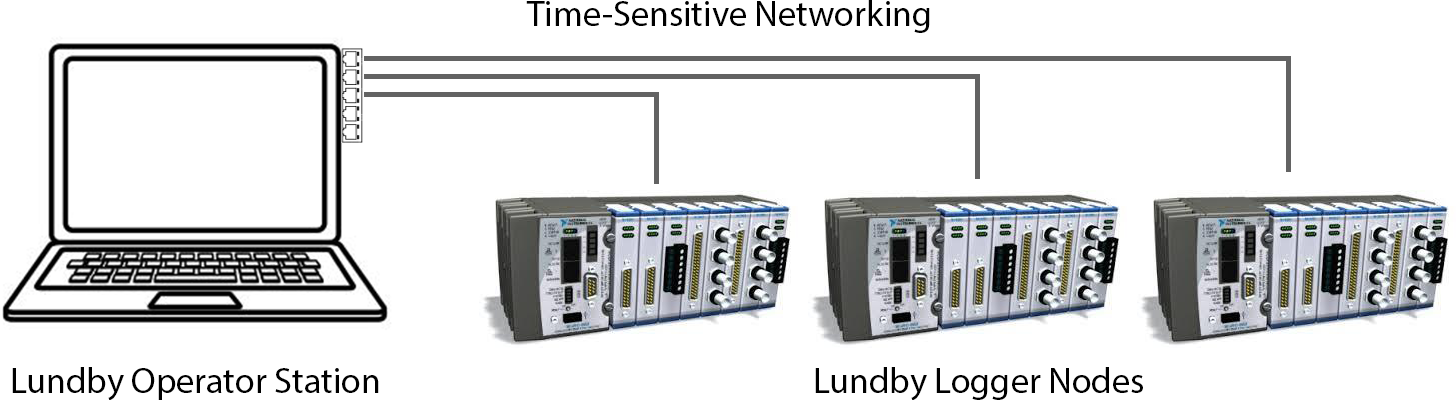

By networking these devices with a Time-Sensitive Network (TSN), Lundby logger becomes a time-synchronized system that can be scaled to thousands of channels and distributed over long distances using ethernet copper or fiber cables.

Figure 2. TSN network with NI CompactRIO, CompactDAQ and FieldDAQ

The project background

Data acquisition systems are indispensable in the operation of nuclear power plants due to their critical role in monitoring, controlling and ensuring the safety and efficiency of various processes. At present, Forsmark is making forward-looking investments aimed at prolonging the facility’s operational life span and capacity for the future. Therefore, upgrading their data logging system to a more advanced, redundant and long-term system has been a priority.

Forsmark’s old data logging system has been used for many years. The main system function was recording as much data as possible whenever there was some sort of disturbance in the power generation or distribution process. Afterwards, the engineering teams utilized the recorded data to investigate and identify the root cause of the disturbance.

The requirements

As the old data logging system became obsolete and the requirement for scalability and acquisition at much higher sampling rate emerged, Forsmark made the decision to upgrade to a modern system. The engineering team at Forsmark did a thorough analysis to determine what requirements they needed to put on the next generation data logger system. Some of the important parameters were:

- Support thousands of I/O channels.

- High sampling rate, at least 200 kS/s.

- A highly distributed, scalable and modular platform.

- Time-synchronized within microseconds, also over long distances.

- Redundant system to be sure recording is made when a trigger occurs.

- Autonomous nodes to ensure offline logging.

- Stable operation that can run 24-7 for years.

- Advanced triggers that include cross-triggering and redundant execution.

- Secured long-term spare parts availability.

- Long-term product warranties.

- Guaranteed long-time qualified support and maintenance.

The evaluation

Forsmark engineers carried out a thorough market analysis to see which alternatives could meet their tough and comprehensive requirements. Systems found were investigated and compared carefully, but no system met all their needs until WireFlow proposed updating their Lundby Data Logger, making it the perfect solution for Forsmark’s needs. These updates included developing complex cross- triggering, TSN synchronization and autonomous nodes with local logging, all of which are available in the product today.

Figure 3. Lundby Data Logger consists of a network with autonomous logger nodes.

The Project

During 2023, WireFlow worked with the upgrade of the Lundby Logger system. Time-Sensitive Networking (TSN) was introduced which enabled synchronization better than one microsecond between data recorded by logger nodes that could be located kilometers apart.

Local offline logging capability at the individual logger nodes was improved. This architecture makes it possible to record thousands of channels simultaneously at extremely high data rates when a trigger occurs.

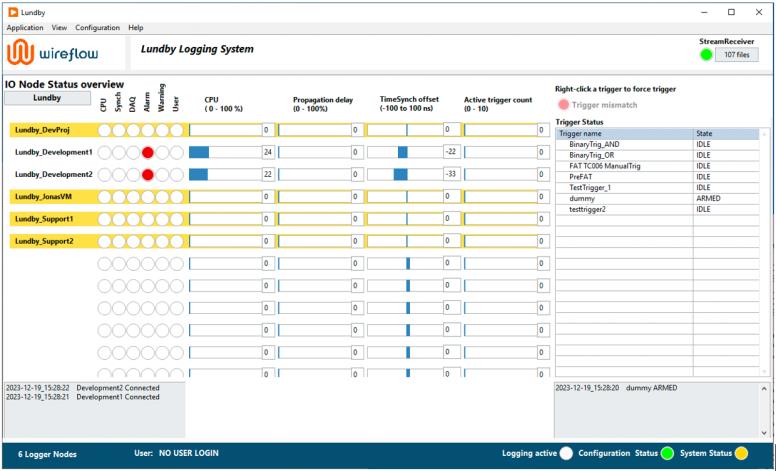

Additionally, Lundby Logger was upgraded with improved status and health monitoring to guarantee that the logger nodes are always ready to start recording whenever a trigger occurs, providing a secure and redundant data logging process all day (24-7).

Figure 4. Lundby system status overview

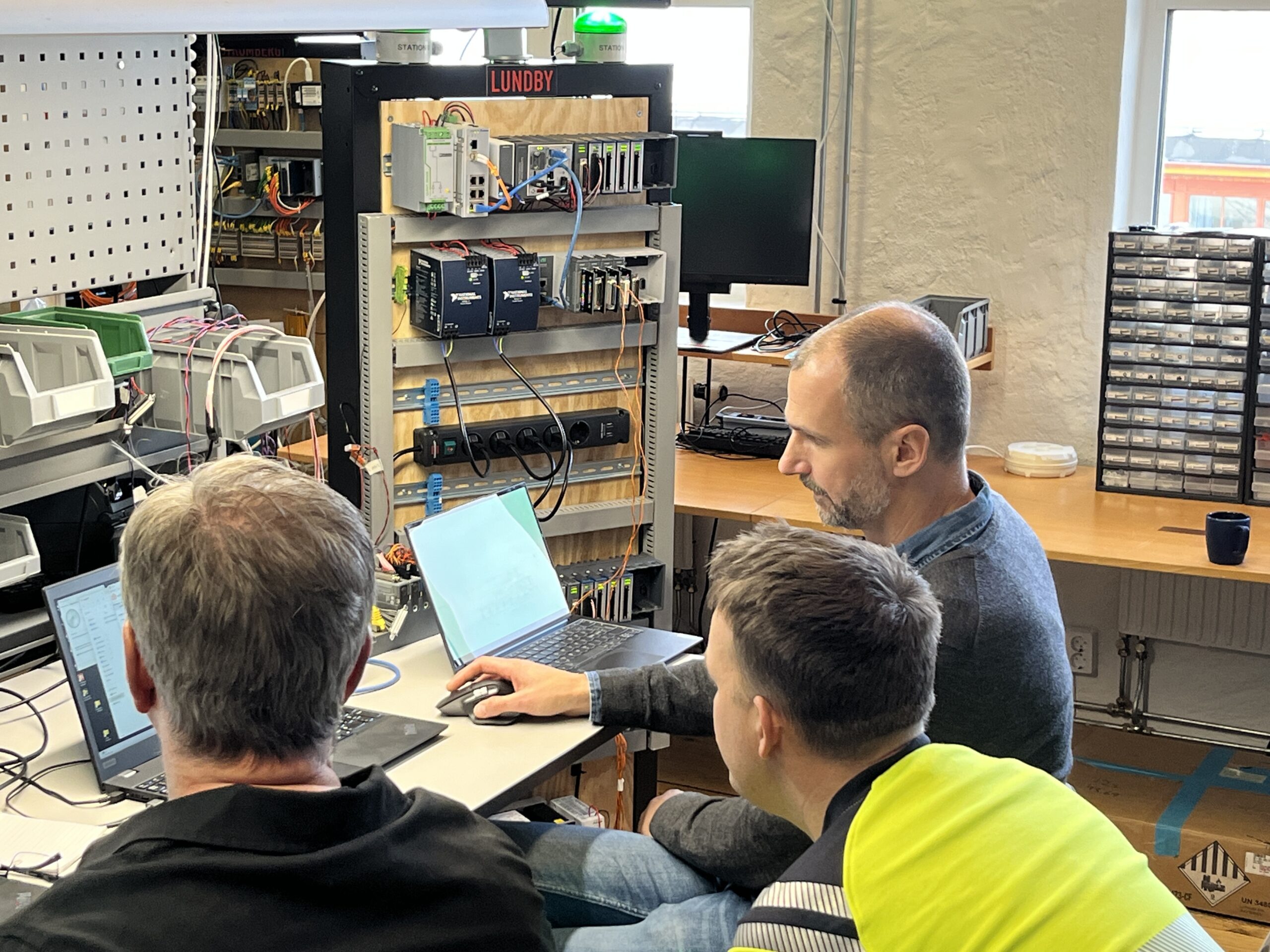

During 2023 and 2024, several training sessions were held where Forsmark’s engineers received thorough training in the Lundby Logger system; enabling. Forsmark to install, configure and maintain the system independently.

In early 2024 a Factory Acceptance Test was performed, and the delivery was then finalized with shipment of network switches, logger nodes, I/O-modules, redundant power supplies etc.

Figure 5. Factory Acceptance Test at WireFlow test lab

Conclusion

The Lundby data logger not only met the current technical demands of Forsmark nuclear power plant as a discerning customer, but also ensured the long-term reliability of the solution as a standard system. Moreover, thanks to the partnership between WireFlow and National Instruments, Forsmark was reassured that scaling up the system and adding more hardware in the future will be hassle-free.

While meeting technical requirements and ensuring long-term spare parts availability were crucial for Forsmark, it was WireFlow’s comprehensive offering that ultimately sealed the deal. WireFlow’s expert team provided a Proof of Concept early in the process and offered educational courses throughout. Additionally, extended warranties and a top-tier support agreement set WireFlow apart from the competition.

”WireFlow will receive a high evaluation score on Forsmark’s Supplier Analysis.”

– Ann-Charlotte Wittborg, Project Manager at Forsmark Kraftgrupp